|

|

Safety

Test of The Relief Vent

|

|

(Controlled By Pressure) |

|

|

|

|

| |

|

|

Cells: 3.2 V 20 Ah & 3.2 V 60 Ah |

|

|

Purpose: Test the effectiveness of GMET relief vent. |

|

|

Design of Relief vent: Vent would open to discharge

pressure when the

Pressure of

vapor of electrolyte inside of cell is

in between

0.25~0.6 mPa (87

psi or 6.11 Kg f/cm²) |

|

|

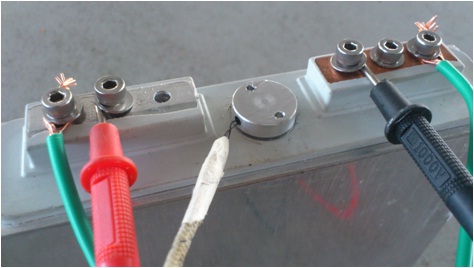

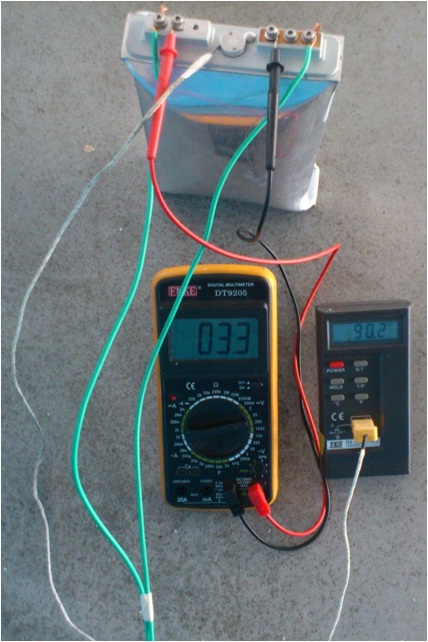

Input : 5V 300 Amp power |

|

|

Ambient temperature of the testing location: 32 ℃ |

|

|

6 points on the surface of cell are monitored. |

|

|

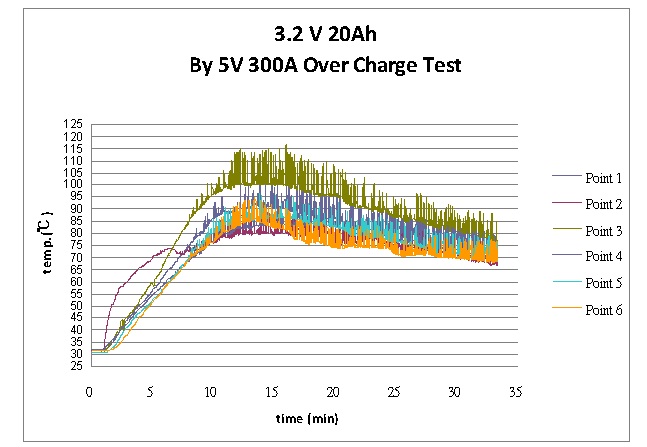

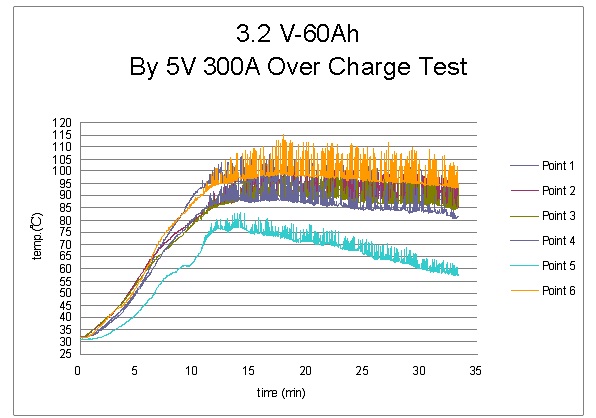

The temperature distribution shows the record of 6 points of

the temperature and time on cell. |

|

| |

|

|

Temperature Distribution during Safety Test |

|

|

|

|

| |

|

|

When a short circuit or over charge occurred in the cell,

the air pressure inside the cell would rise higher and

higher till it breaks the shell or explosion. With a GMET

design controlled by pressure relief vent, the vent on

battery cell would open when the air pressure inside the

cell higher than 0.2~0.6 mPa (87

psi or 6.11 Kg f/cm²).

From the ideal

gas law

PV=nRT, to monitor the temperature is a proper parameter to

evaluate the effectiveness of pressure controlled relief

vent.

The 6 points of temperature on the surface of cell were

monitored, the temperature of battery cell can’t higher than

105 ℃ after the relief vent discharged at the controlled

pressure range.

The temperature inside of cell might higher than what the 6

points measured. However the 105 ℃ peak and down turn of the

temperature curve shows the temperature inside cells won’t

get higher. It proved the relief vent working and the cell

won’t get flame or burning and no risk of explosion.

If something occurred on the battery cells, the temperature

of GMET cell through designed relief vent working would

still less than 105 ℃. Since the temperature of cells won’t

higher than 140 ℃, there is no chance for GMET cells to

reach thermal runaway temperature. It is the safety of the

GMET cell. |

|

| |

|

| |

|

|

Test of The Advanced Design Relief Vent |

|

(Controlled By Temperature) |

|

|

|

|

|

|

|

|

|

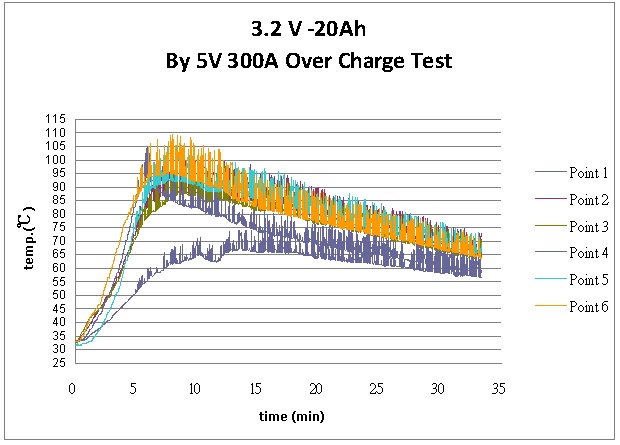

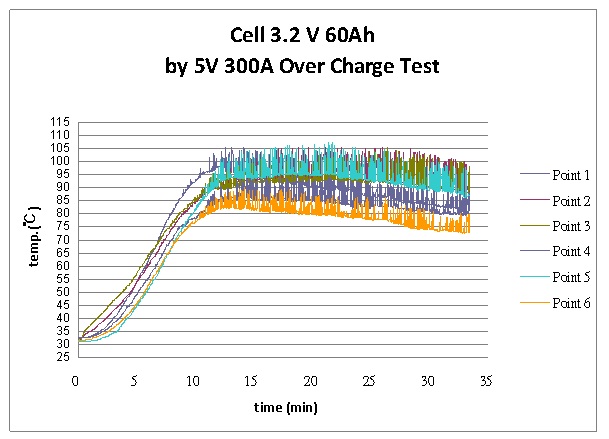

Cells: 3.2 V 20 Ah & 3.2 V 60 Ah |

|

|

Purpose: Test the effectiveness of the advanced design GMET

relief vent. |

|

|

Design of Relief vent: Vent would open to release pressure

when the

temperature of

vapor of electrolyte is higher than 95 ℃. |

|

|

Input : 5V 300 Amp power |

|

|

Ambient temperature of the testing location: 32 ℃ |

|

|

6 points on the surface of cell are monitored. |

|

|

The temperature distribution shows the record of 6 points of

the temperature and time on cell. |

|

|

|

|

Temperature Distribution During Safety Test |

|

|

|

|

|

|

|

Observation of the Temperature Distribution |

|

When a short circuit or over charge occurred in the cell,

the temperature of cell is getting higher and higher till it

breaks the shell or explosion. With a GMET advanced design

relief vent, from the 6 points temperature curve monitored,

the temperature of battery cell after relief vent worked

can’t higher than 100 ℃ and it also shows the temperature

curve down turn. The temperature inside of cell might higher

than what the 6 points measured. However it proved the vent

working and the cell won’t get flame or burning and no risk

of explosion.

If abnormal situation occurred on the cells, the temperature

of GMET cells through the working of relief vent would still

less than 100 ℃. Since the temperature of cells won’t higher

than 140 ℃, there is no chance for GMET cells to reach

thermal runaway temperature. This is the safety of the GMET

cells. |

|

|

|

|

|

|

|

|

|